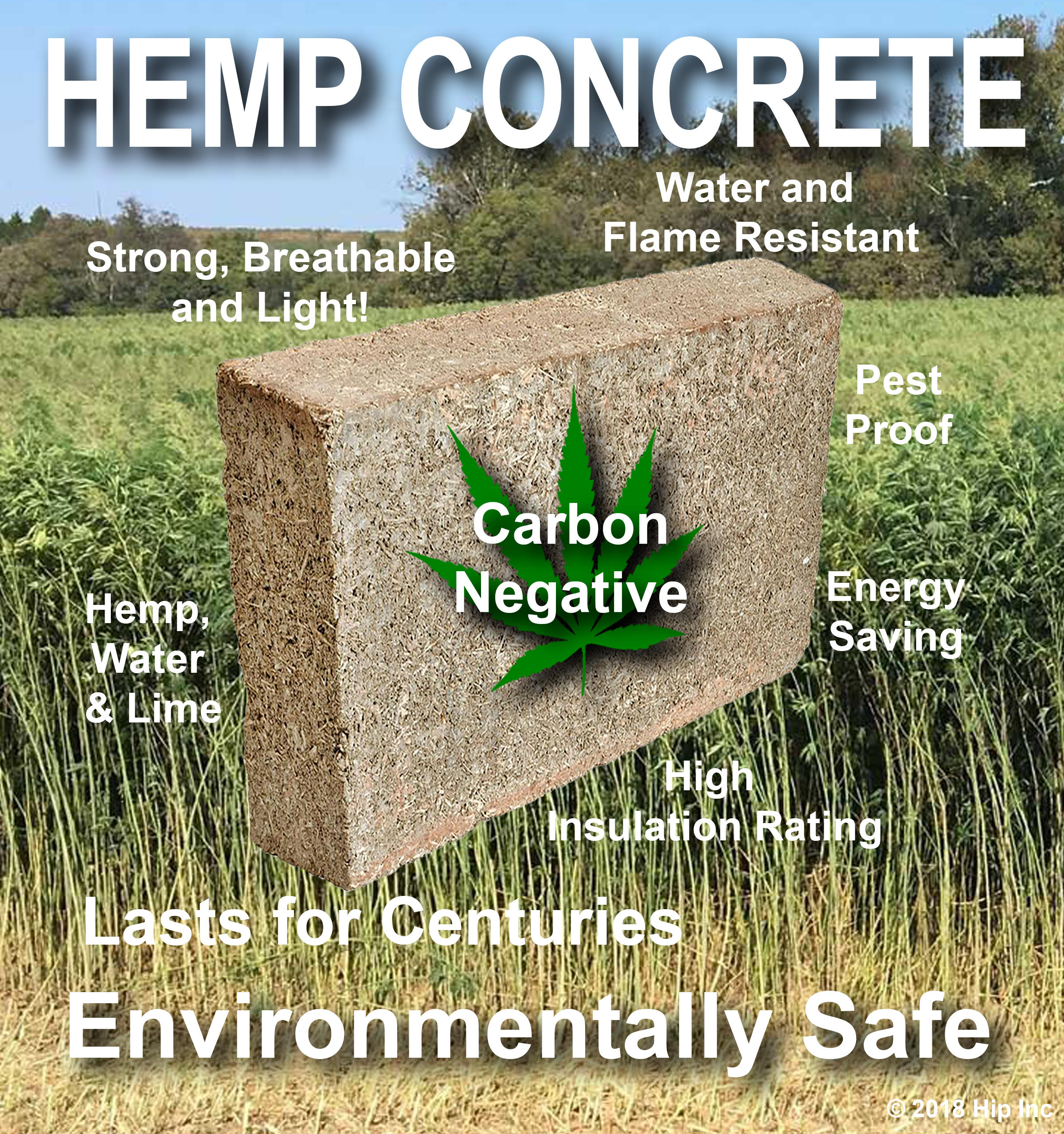

Build a Home with Hemp Concrete

Hemp concrete is something from the earth,

combined with something grown in the earth,

which shelters you and is good for your health.

Hemp concrete is perhaps the best alternative building material I have stumbled across yet. I have investigated straw bales, adobe, sun fired bricks, concrete blocks, and used shipping containers. None of these have the long-lasting health and environmental benefits that hemp offers.

Hemp concrete is a bio-composite material made from a resin matrix with natural hemp fibers for reinforcement. The resin in hemp concrete is made from lime (possibly including natural hydraulic lime, sand, and volcanic ash known as pozzolans).

The natural mineral (native lime) CaO occurs as a product of coal seam fires and in volcanoes. Commercially it is produced in vast quantities, made by heating limestone or seashells to above 825 °C (1,517 °F) in a lime kiln.

The hemp part consists of hemp hurds. Hurds are the woody inner portion of the hemp stalks which are broken into pieces and separated from the fibers used for other purposes.

Hemp concrete is commercially available under such names as Hempcrete, Canobiote, Canosmose, and Isochanvre. People who work with it say it is easier to use than regular concrete, and offers moisture regulating and insulation properties to the building itself not found with other materials.

Hemp concrete is a sustainable substance being made from plant material easily grown almost anywhere. The making of Hemp concrete has negative carbon emissions. Growing all that hemp actually takes more CO2 out of the air than it releases.

Specific reasons to use hemp concrete:

- Flexibility under stress means it is much more suitable for earthquake prone regions than brittle traditional concrete which shatters easily.

- The insulation factor of hemp concrete is a big plus. The incredibly high R-Value (insulation power) of hemp concrete will reduce energy costs for heating and cooling. A 12-inch wide hemp concrete wall has an R value of 30 and a 16-inch wall has an R value of 40. Walls in conventional home constructions have ratings less than half of that, and need further insulation layers.

- Hemp concrete is highly fire resistant.

- Lightweight hemp concrete use means there is less pressure on the load-bearing parts of your house, resulting in a shallower, less-expensive foundation.

- Termite and bug-resistant.

- Mold resistant.

- Breathable walls naturally regulate indoor humidity.

- Rot resistant. As the hemp concrete ages, the hemp hurds turn into petrified stone.

- Hemp concrete homes are healthier, absorbing excess humidity indoors as it builds up when cooking or when the house is closed, releasing it later when the relative humidity drops again.

How about the cost?

Until more commercial hemp is grown and offering hurds to the building industry, the cost of a hemp concrete home will be about double the price per square foot of a similar stick-built mass-produced tract home (in 2009). Now, in 2018, 17 states DO allow hemp, and prices may be tumbling. Even if the price is drastically reduced, the price of custom built homes of any type are more expensive than others.

If you are environmentally conscious, and wish to build something that lasts, consider hemp concrete.

Hemp concrete blocks being used to build a wall.